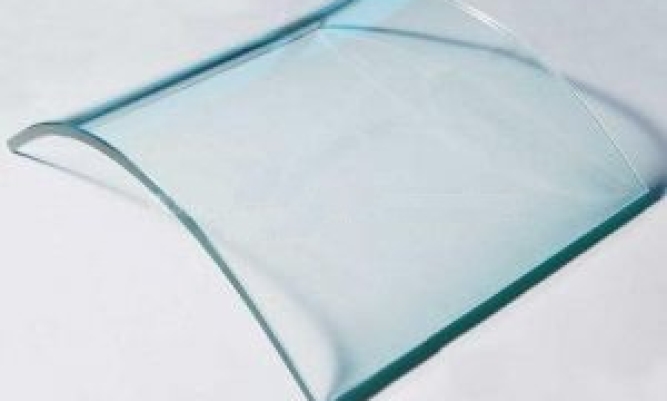

Hot bent glass is a type of curved glass that is softened by heating and molded in a mold, and then annealed to produce various irregular curved surfaces. It has aesthetic and specific properties and can be made into various irregular curved surfaces. Hot bending glass technology is mainly divided into three categories: single bending, bending, and composite bending. The hot bending process involves heating glass to a certain temperature to soften it, then bonding it with a mold under pressure, and cold cutting it by holding pressure and gradually cooling it down to form 3D shaped glass. The process flow of hot bending glass includes steps 2 such as cutting, edge grinding, ultrasonic cleaning, hot bending, double-sided polishing, chemical strengthening, screen printing and spraying, AF treatment, etc.

Hot bent glass has a wide range of applications in buildings and civilian settings, such as fish tanks, dining tables, balconies, mobile phone counters, cosmetics counters, hot bent TV cabinets, doors and windows, ceilings, curtain walls, etc. The beauty of hot bent glass is reflected in its seamless curved shape and overall harmonious lines. The production of hot bent glass can meet the special requirements of customers, producing composite products such as hollow and sandwich layers, and can be customized.

The hot bending glass technology faces some challenges in the production process, such as the problem of matching the mold at the curved edge 150mm away from the straight edge of the product, mold mark defects in bent glass, and low yield of ultra large deep arc glass. During the hot bending process, the mechanical properties of the glass need to be considered to avoid explosion caused by exceeding the allowable stress. The selection and operation process of molds in hot bending technology have a significant impact on product quality, including the type of mold, preheating method, temperature control, annealing process, etc.

The superior performance of hot bent glass includes high appearance, good touch, lightweight, transparent and clean, anti fingerprint, anti glare, good weather resistance, etc. These characteristics make it widely used in 3C product design, such as smartphones, smartwatches, tablets, etc. However, there are also some problems with the hot bending process, such as high energy consumption, low mold life, large dimensional tolerances, and warping deformation after tempering, which need to be solved through optimized design and process control.

Overall, hot bent glass is a glass product with a wide range of applications and unique advantages, but it also faces some technical and process challenges. With the advancement of technology and the growth of market demand, the development prospects of hot bending glass are broad.